Low-Viscosity Pure Epoxy Chemical Anchor 585ml Deep Penetration Adhesive for Cracked Concrete

GU-500SD pure epoxy chemical anchor has successfully received the European Technical Assessment report ETA-24/0928, confirming its high performance and reliability for structural applications. The assessment was conducted in accordance with EAD 330087-01-0601, covering a wide range of conditions including high alkalinity environments, sulphurous atmospheres, corrosion resistance, and fire exposure performance. This high-performance pure epoxy chemical anchor is specifically engineered for rebar connections and heavy-duty anchoring in dry, wet, and uncracked concrete. Its advanced formulation delivers exceptional bonding strength and long-term durability across a wide temperature range, making it a reliable choice for even the most demanding structural applications.

Product Features

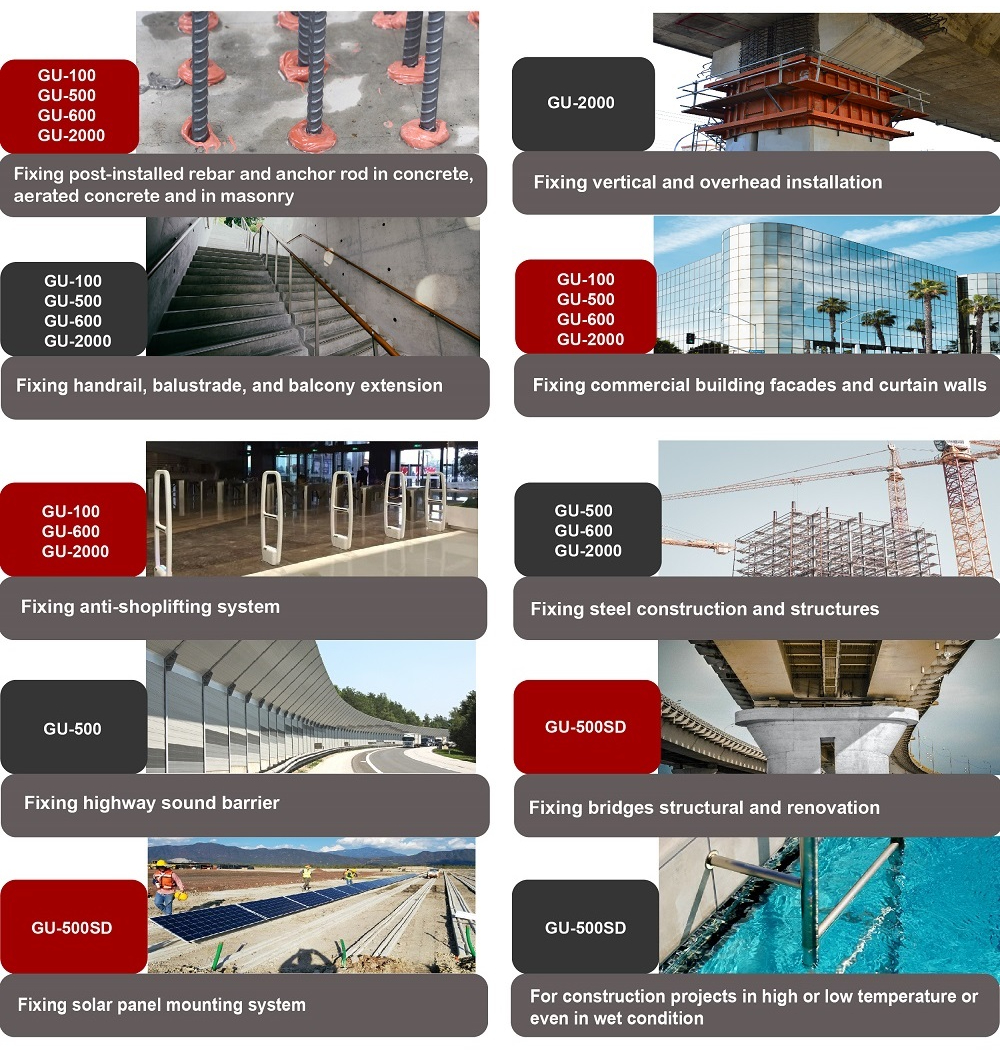

Application

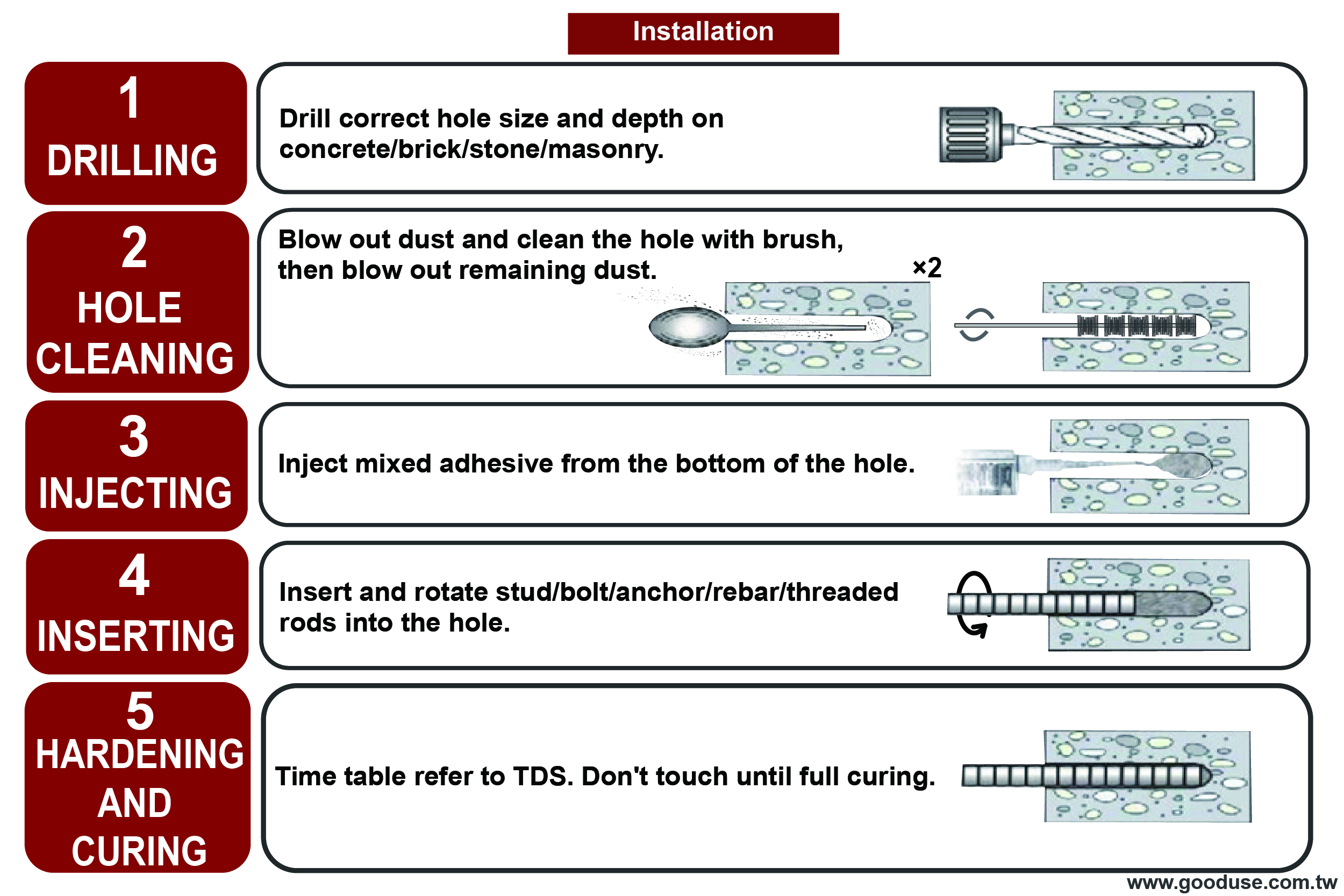

Installation

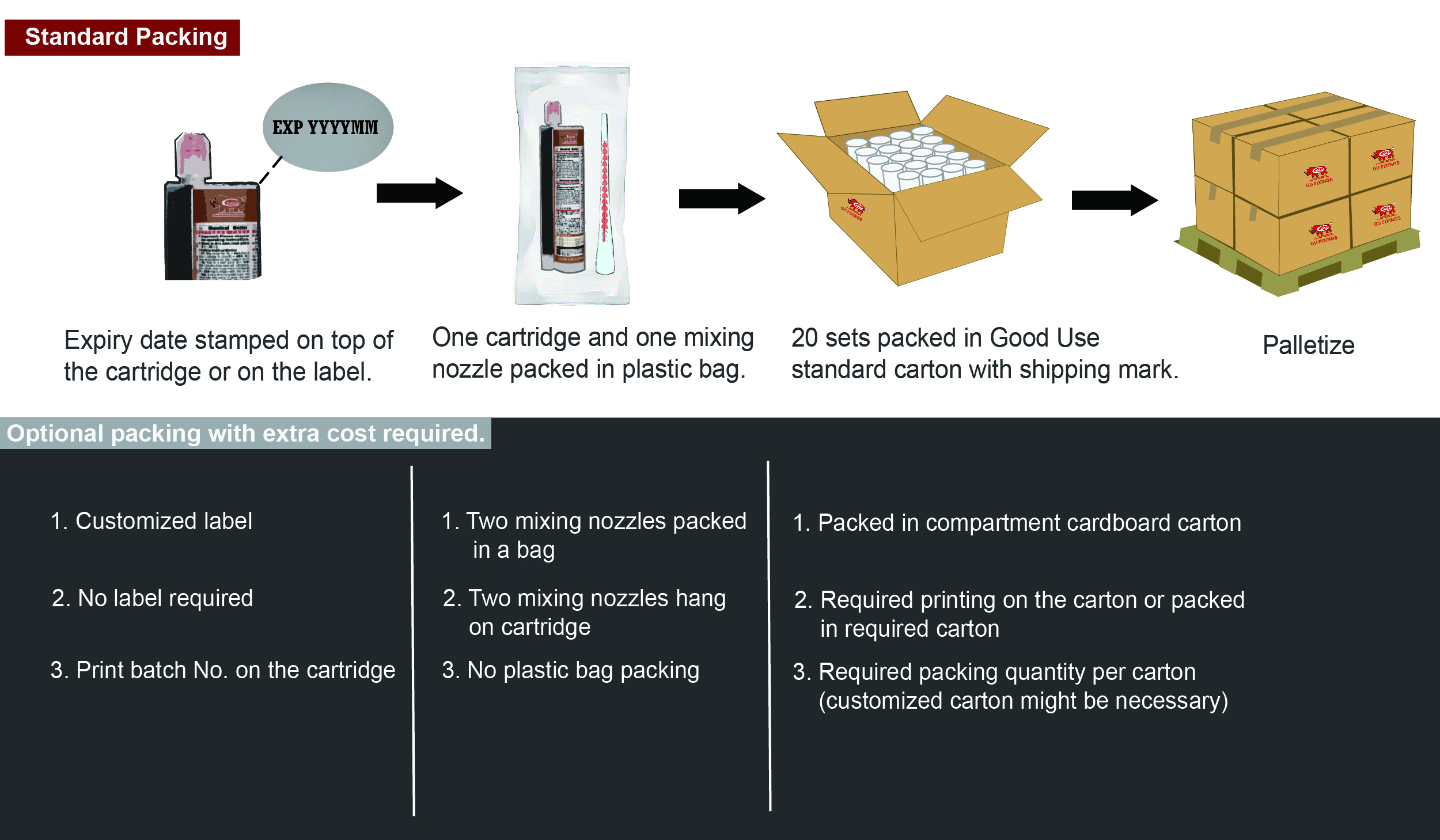

Packing & Shipping

- Standard Packing:1 tube + 1 mixer per set, 20 sets per box.

- Shipments can be arranged by sea, air, courier express.

- Courier express includes DHL, FedEx, UPS, EMS, SF, etc.

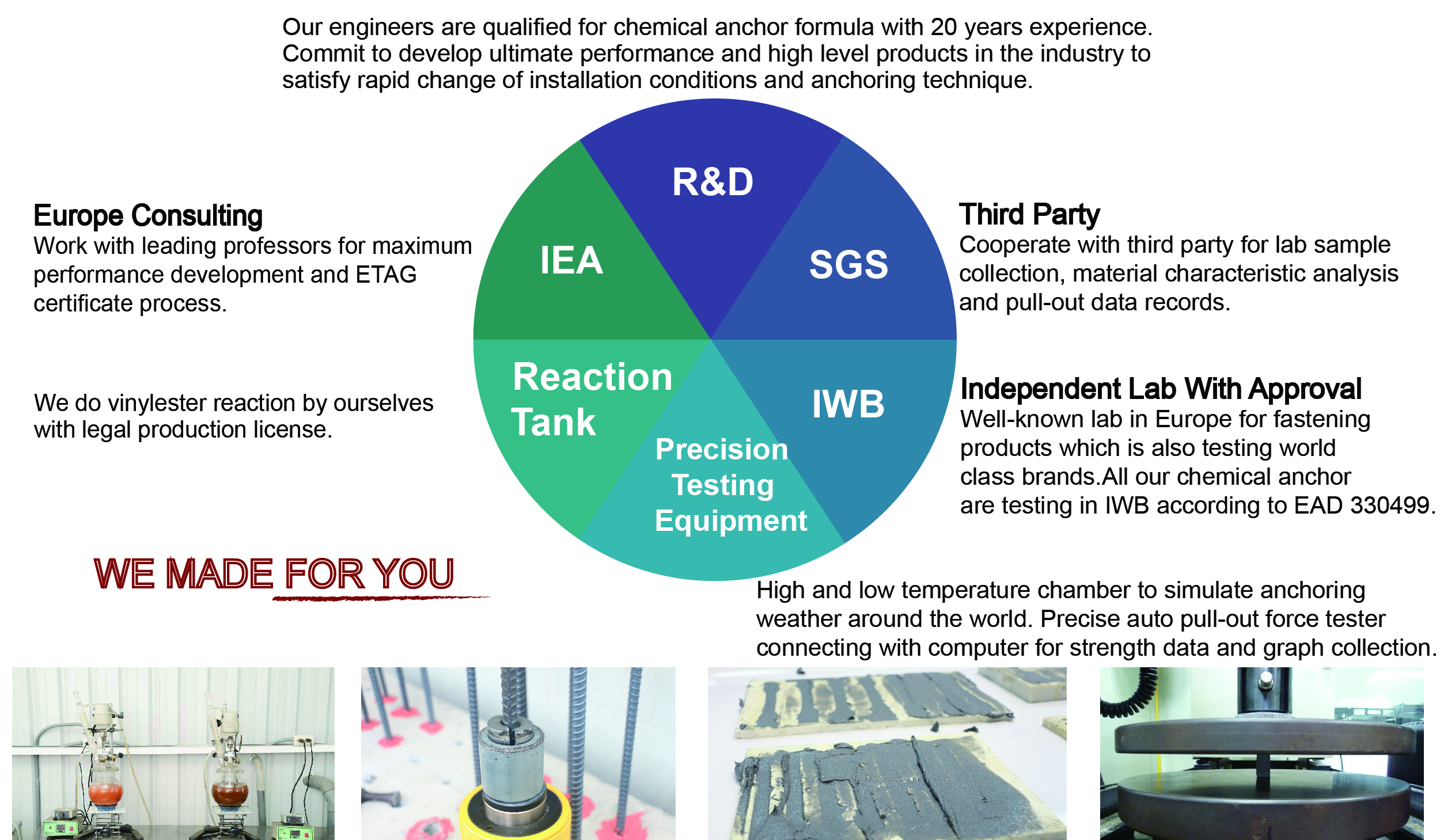

Company Overview

Why Choose Us

Quality Control

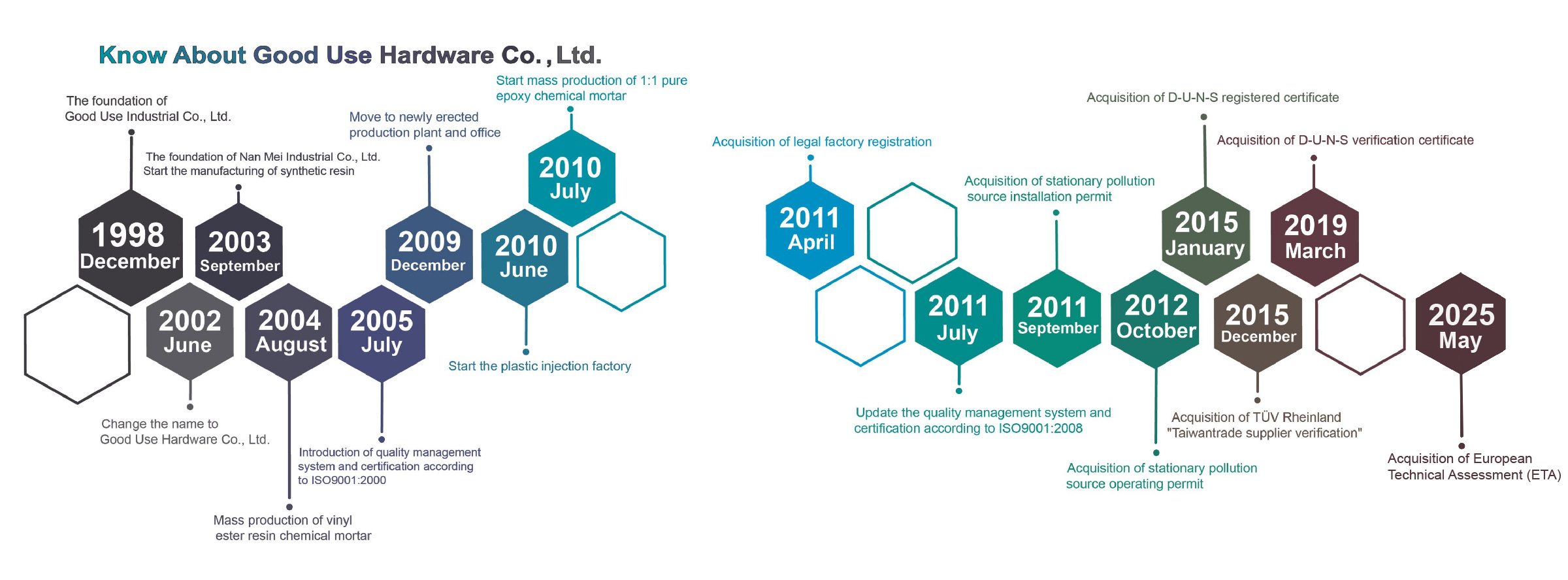

Milestone

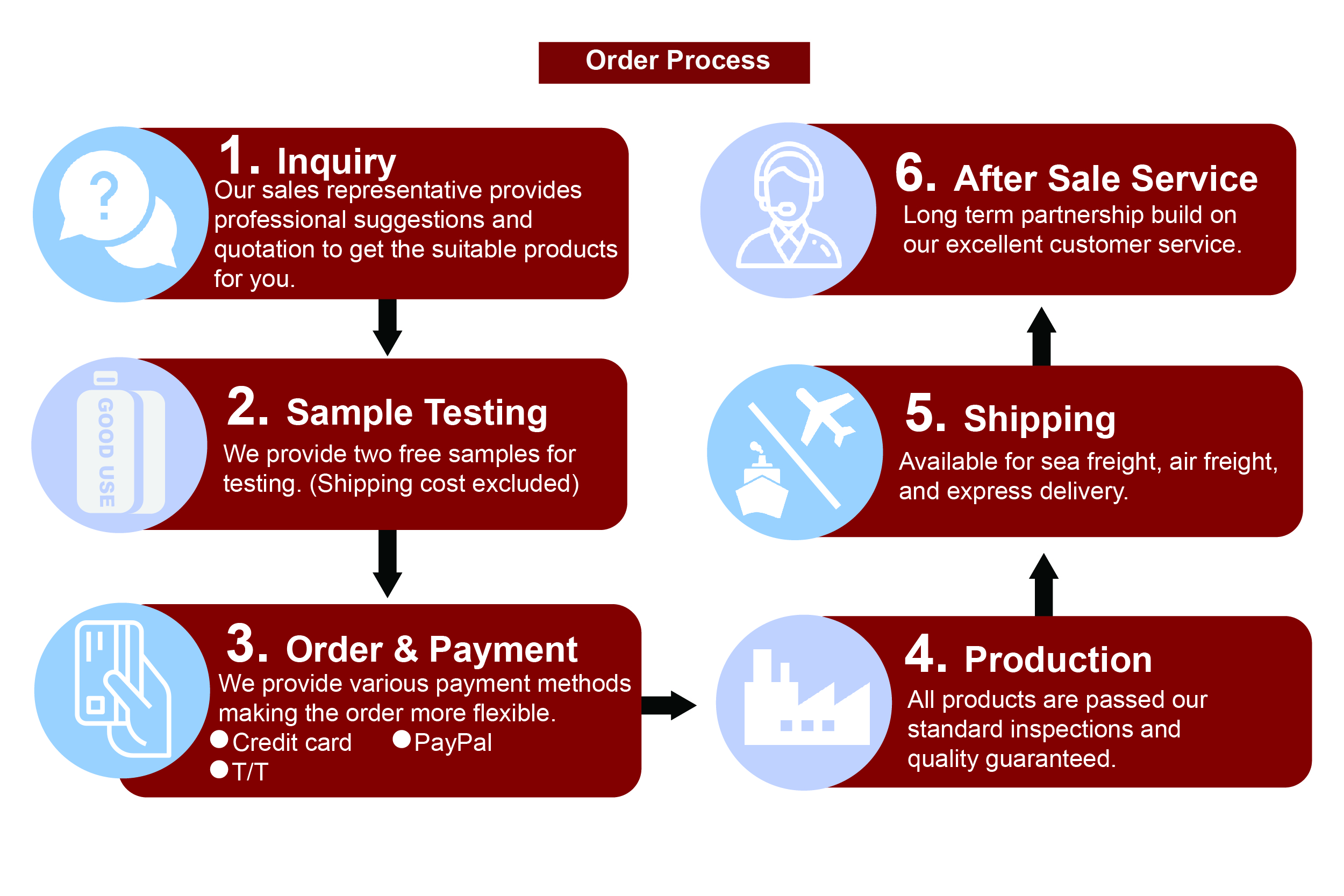

Easy Order Process

~~~~~~~~ Visit our website http://www.gooduse.com.tw/ for more information. ~~~~~~~~